Hidden Environmental Cost of E-Mobility: New Study Reveals Massive Mining Waste from Electric Vehicle Production

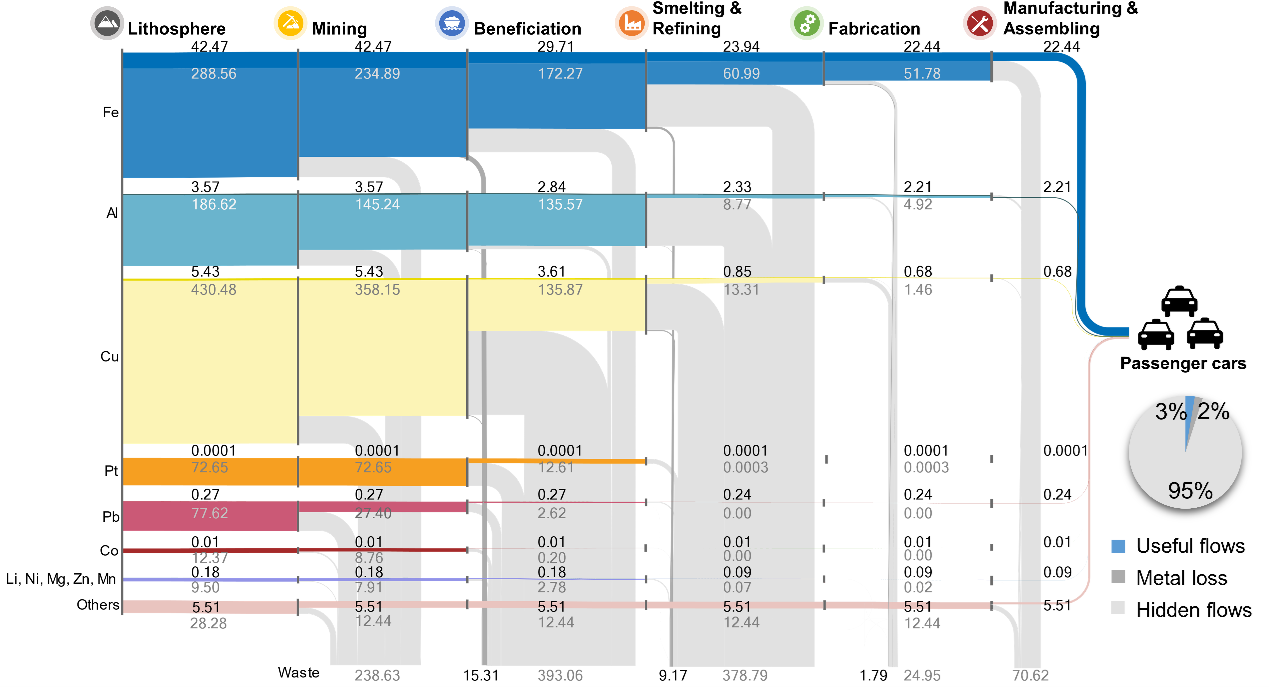

Associate Professor Wu Chen from the University of Southern Denmark (SDU) has co-authored a groundbreaking study revealing that the global shift to electric vehicles generates far more mining waste than previously understood. The research, recently accepted by Nature Communications, quantifies for the first time the complete “hidden flows”—mining waste including overburden, waste rock, and tailings—along China’s passenger car supply chain.

Alarming Findings

Using China as a case study (the world’s largest NEV producer and consumer), the international research team led by Professor Kazuyo Matsubae (Tohoku University) and Professor Gang Liu (Peking University) found that:

- A new energy vehicle (NEV) generates over 3 times the hidden flows of a conventional vehicle.

- Hidden flows exceed eventual used resources by 35 times, with only 3% of extracted materials entering the car sector.

- 1,163 million tons of materials were extracted to produce China’s passenger cars in 2019, generating 1,106 Mt of mining waste.

- 48% of these hidden flows occur outside China, primarily in Chile, Australia, Peru, and South Africa.

Innovative Methodology

The study developed a global mine-site-specific database covering 1,784 mines across 11 metal minerals and created a life-cycle-based Total Material Requirement (TMR) framework. This high-resolution approach reveals that critical battery materials—lithium, cobalt, and nickel—though comprising only 0.4-9.5% of direct material flows, contribute 6-41% of hidden flows per vehicle.

Path Forward

The research identifies concrete mitigation strategies:

- Recycling copper (which contributes 37% of hidden flows) could reduce total waste by 35%.

- Switching from NMC/NCA batteries to LFP batteries could achieve 3–12% reduction.

- Clean energy transition in smelting and refining could reduce hidden flows by 13–14%.

“About half of these hidden flows occur abroad, revealing an unequal distribution of environmental burdens,” notes the research team. “Achieving a sustainable e-mobility transition requires coordinated international cooperation along the entire supply chain—from mining countries improving extraction practices to manufacturing countries adopting responsible sourcing and efficient product designs.” The findings underscore the need to balance greenhouse gas reduction goals with broader environmental sustainability, ensuring that the transition to electric mobility doesn’t simply shift environmental problems from emissions to mining waste.

Paper status: Accepted by Nature Communications (in press)

Nature Communications is a premier open-access multidisciplinary journal publishing high-quality research across all areas of the natural sciences.